Brass gas valves are an essential component of gas appliances that regulate the flow of gas. These valves control the amount of gas that is released, ensuring that the appliance functions safely and efficiently.

Functions of Brass Gas Valves

Brass gas valves are primarily responsible for controlling the flow of gas in gas appliances, such as heaters, ovens, and boilers. These valves have two basic functions: to open and close the flow of gas and to regulate the flow of gas.

When the valve is opened, gas is allowed to flow through the valve and into the appliance. This process is usually controlled by a knob or lever that is connected to the valve. By turning the knob or lever, the user can open or close the valve.

In addition to controlling the flow of gas, brass gas valves also regulate the pressure of the gas. The pressure of the gas is important because it determines how much gas is released at any given time. If the pressure is too high, there is a risk of explosion or fire. If the pressure is too low, the appliance may not function properly.

Types of Brass Gas Valves

There are two main types of brass gas valves: ball valves and globe valves.

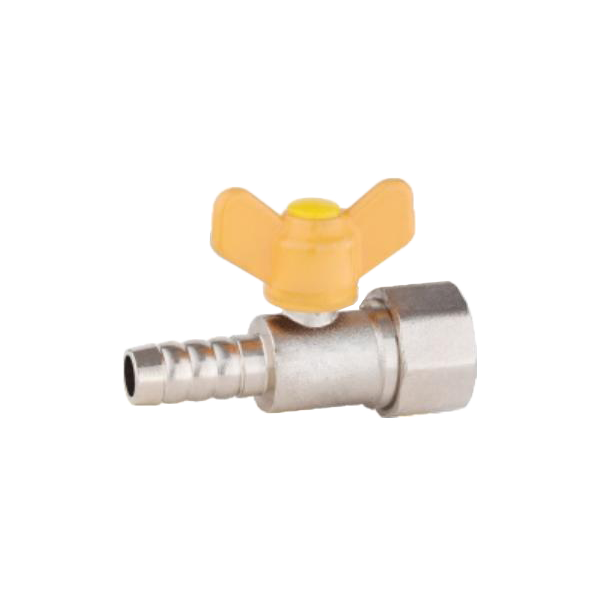

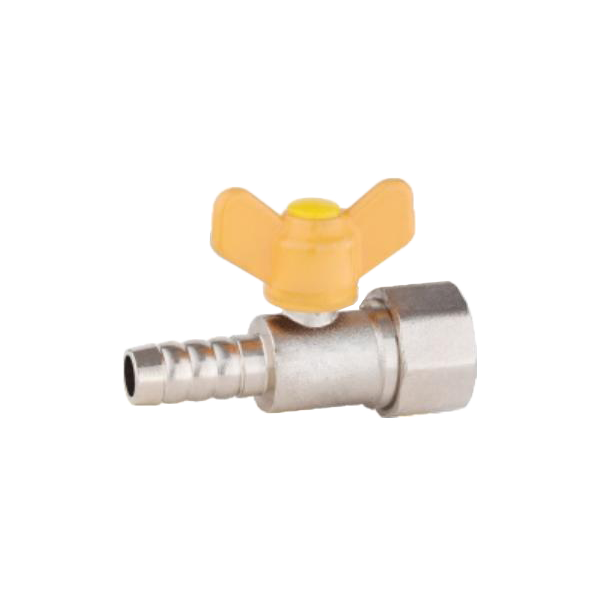

Ball valves are designed to allow gas to flow in one direction only. They are operated by a lever that is turned 90 degrees to open or close the valve. When the lever is turned, a ball inside the valve rotates to control the flow of gas.

Globe valves, on the other hand, are designed to regulate the flow of gas in both directions. They are operated by a wheel that is turned clockwise or counterclockwise to open or close the valve. When the wheel is turned, a disk inside the valve moves up or down to control the flow of gas.

Maintenance of Brass Gas Valves

Proper maintenance of brass gas valves is important for ensuring the safety and efficiency of gas appliances. Regular maintenance can also help to extend the lifespan of the valve.

One of the most important aspects of maintenance is checking for leaks. Leaks can occur due to worn or damaged valve components, such as the seals or gaskets. If a leak is detected, the valve should be repaired or replaced immediately to prevent a potential gas explosion.

In addition to checking for leaks, brass gas valves should also be cleaned regularly. Dirt and debris can build up inside the valve, causing it to malfunction. To clean the valve, it should be disassembled and the parts should be wiped clean with a soft cloth. The valve should then be reassembled and tested for proper function.

Brass gas valves are an essential component of gas appliances. They regulate the flow of gas and ensure that the appliance functions safely and efficiently. There are two main types of brass gas valves: ball valves and globe valves. Proper maintenance of brass gas valves is important for ensuring the safety and efficiency of gas appliances. Regular maintenance can also help to extend the lifespan of the valve. By understanding the functions, types, and maintenance of brass gas valves, consumers can ensure the safe and efficient operation of their gas appliances.

Material : Brass

Greatest pressure : 1.6MPa

Medium : Gas

Temperature : 0-100℃

Thread standard : ISO228