The manifold is the heart of your

underfloor heating system. Its job is to maintain an even temperature of the floor area and to make sure that the correct amount of water is circulating through each zone. When you install your system, the manifold must be installed by a professional to ensure that it is safe and effective. If it is not, it may cause damage to your home.

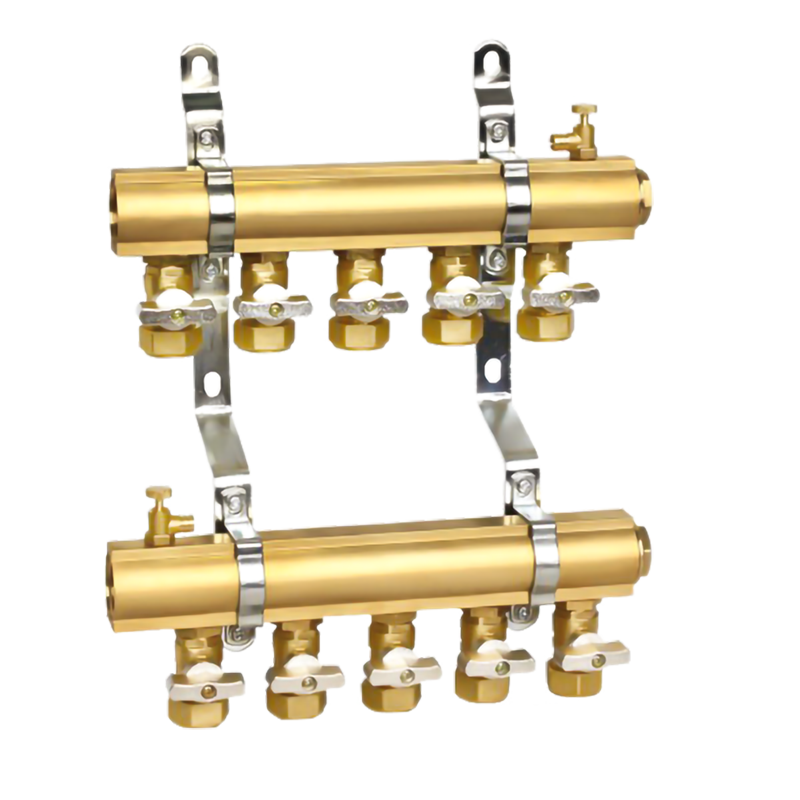

The manifold has an array of components that include a flow bar, isolation valves, blending valves, and flow gauges. They help to control the water's flow through the individual floor circuits and enable individual room control. Each of these elements must work together in order for the system to function correctly.

Manifolds usually have an air vent placed on the flow bar. This vent helps to remove air from the system. Additionally, they are designed to allow small amounts of air to be expelled when it is needed. Depending on the layout of your house, the manifold may be located near the central heat source.

The manifold also contains isolation valves, which are linked to the manifold bars. These valves isolate the manifold to prevent any conflict with the primary floor circuits. Some manifolds have valve pins affixed to the isolation valves. Other manifolds are designed to fit with a certain type of pipe.

Another important component of an underfloor heating manifold is a pump. A pump is used to move the water through the different loops. There are several types of pumps available, but most of them are designed to operate at low pressures. In the event that the pump is not functioning properly, it may not be possible to heat the floor.

In addition, the manifold has a number of taps. Each bar contains up to twelve faucets. One of the taps is a filling and drain off valve. These two valves are used during the initial filling of the underfloor heating system.

There are also a number of actuators that are attached to the manifold's commissioning valves. Actuators help to open and close each of the floor circuits. Actuators are connected to a wiring center, which enables them to open and close all of the valves.

These manifolds can be very complex to install. However, if you are confident about laying the pipework yourself, you can have your system set up in no time. You must consider the specifications of the system and the end user's wishes.

The number of taps in an underfloor heating manifold depends on the size of the system. Generally, the maximum allowed temperature is around 55deg C. During severe frost, this limit may be lower. To ensure optimum thermal comfort, you should always adjust the supply temperature according to weather conditions.

Using a flow meter instead of a supply valve can also help you achieve the proper hydronic balance. With a flow meter, you can have accurate information about the flow rate of each individual zone.

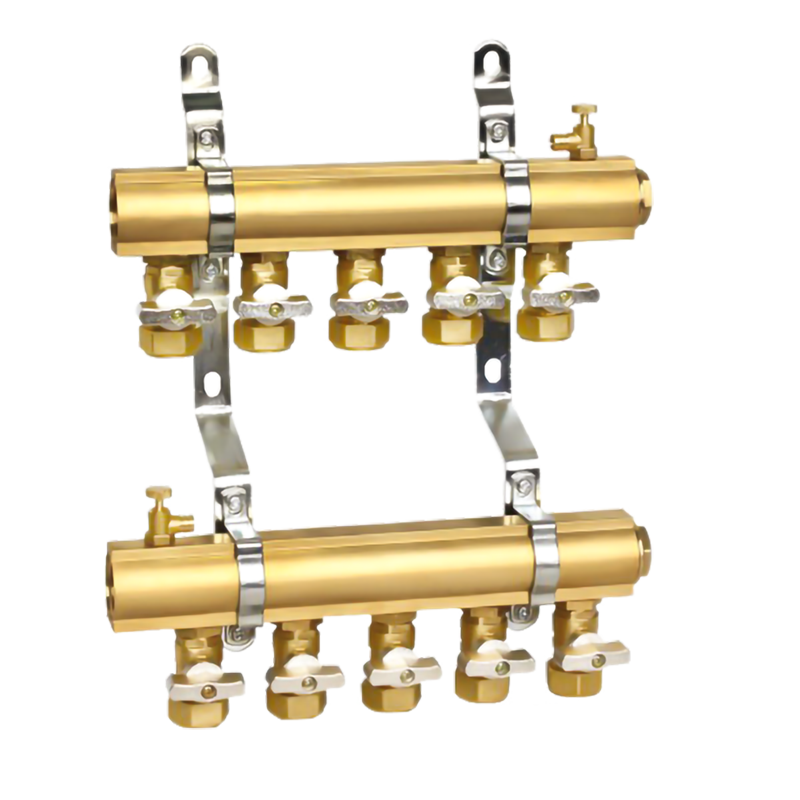

Material: The main raw material of the copper pipe connector is HPb58-2 bar material, and the specification range is Ф16~Ф100 to produce different types of products. The metal content of the material ratio is as follows: Cu 57~61% Pb0.8~2.5% Zn36~40%, impurity content range: Sn, P, Mn, Fe, Ni, Mg, As, Sb, Al, S total not allowed to exceed 2% is recognized by the non-ferrous industry as the best raw material for the manufacture of various valves, pipe connections, precision instruments, and watch parts.

Application range: It is widely used in the pipeline system of cold, hot water, acid, alkali, salt and other liquids and gas, oxygen, compressed air and other media.